Common error in digital distance measurement

Digital distance measurement is the process of measuring the distance between two points using digital technology. This technique has revolutionized the way distance measurement is performed in many industries, such as construction, surveying, and engineering.

In traditional methods, distance measurements were taken using tape measures or other mechanical devices, which were often time-consuming and required a great deal of effort to get accurate measurements. Digital distance measurement, on the other hand, uses advanced electronic technology to provide faster, more accurate measurements.

One common digital distance measurement tool is the laser distance meter, which uses a laser beam to accurately measure distances. These meters are compact, lightweight, and easy to use, making them ideal for a wide range of applications.

Digital distance measurement technology has several advantages over traditional methods. It provides faster and more accurate measurements, reduces the risk of errors, and allows for measurements to be taken in difficult-to-reach or hazardous locations. Additionally, digital measurements can be stored and analyzed on a computer, making it easier to create accurate 3D models and maps.

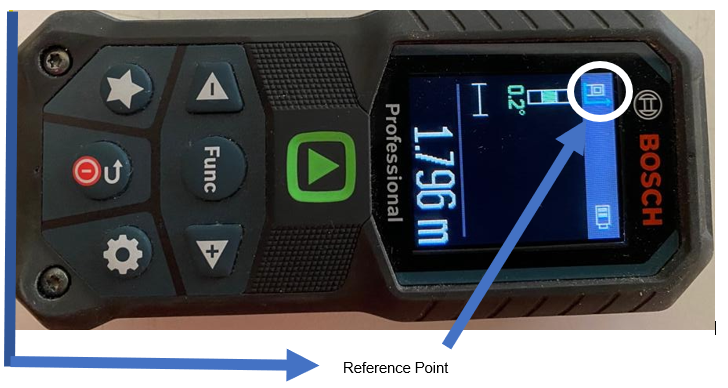

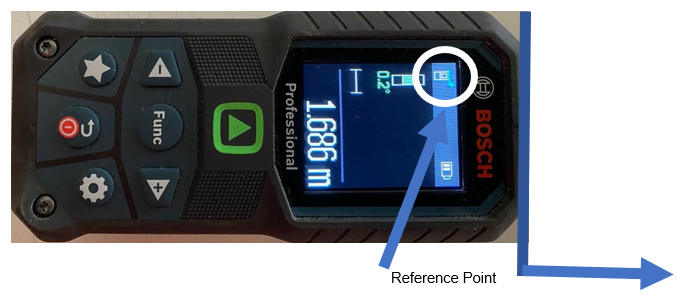

Most common error in digital measurement is the reference point of measurement. One has to observe in the tool the reference point indicated to take the reading. Below three example will give three different reading if reference point is not selected properly.

Figure -1 Above reading shows the measuring point reference as bottom of the tool. All measurement will be taken from this point. Same point is indicated in the image on the screen which is in circle.

Figure -2 Above reading shows the measuring point reference as centre of the tool. All measurement will be taken from this point. Same point is indicated in the image on the screen which is in circle.

Figure-3 Above reading shows the measuring point reference as front of the tool. All measurement will be taken from this point. Same point is indicated in the image on the screen which is in circle.

One may observe an error of 25 to 100 mm in case of wrong reference selected, hence when using a digital hi-tech device one has to be careful on reference point of measurement.