Field test procedure for Auto / Optical Level

This description is suitable for semi-skilled person.

How to check Auto / Optical Level for its levelling error. The procedure described is two peg test method. We have taken GOL 32D of Bosch make in this test procedure. Items required for this test are Two levelling rod, one optical level and one tripod stand. Tripod stand has to be very sturdy and should be able to stay firm without shaking.

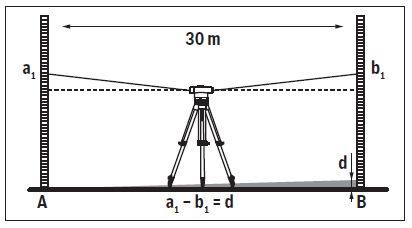

Place the levelling rod / scale at 30 meters apart as shown in below diagram. Now place the optical / auto level at approx. middle of the two staff. Mark of the rod as “A” and the other as “B”. Align the tool levelling, keeping the bubble in the centre. Turn the optical level 180 degree and ensure the levelling bubble in the centre of the vial located on the optical level.

Focus the optical level to scale marked as “A” write the reading value as a1. Now focus the optical level with out disturbing any setting to scale marked as “B” (adjust focus gently if necessary) write the value as b2. Now subtract a1 to b1 value obtained d will be level height difference.

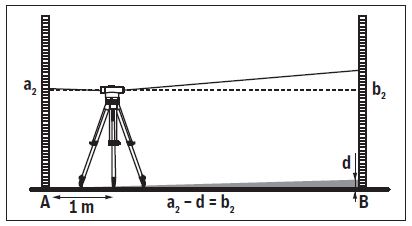

Move the optical level with tripod stand to scale marked as “A” and place it at a distance of approx. 1 meter. Focus the optical level to scale marked as “A” write the reading value as a2. Subtract d previously obtained value from a2. Now turn the optical level to scale “B” you should get the value equal to subtracted a2 value. Else record the value in scale “B” this is the deviation value observed. To get best result repeat the procedure minimum 5 times. If deviation value is greater than specified or required value contact the service team or NABL certified calibration laboratory for necessary correction.

Note: All along the measurement series cover the auto / optical level, so that sun light does not fall on the instrument directly. Else near to true deviation may not be obtained. Also note this is not a calibration procedure. For calibration contact the company personnel or NABL certified laboratory.