Why calibration of optical level is important

Calibration of an optical level is essential to ensure that it provides accurate and reliable measurements. Over time, environmental factors and wear and tear can cause the level’s components to shift or become misaligned, which can affect the accuracy of its readings. This is especially important in construction and engineering projects, where even small errors in measurements can have significant impacts on the overall outcome of a project.

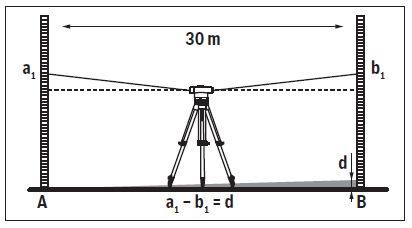

Calibration involves the process of checking and adjusting the instrument’s components to ensure that they are functioning correctly and providing accurate readings. This is typically done using specialized equipment and techniques to verify that the level is aligned and calibrated to the correct standards.

Failure to calibrate an optical level can lead to errors in measurements, which can cause significant problems in construction and engineering projects. For example, if a building’s foundation is not levelled correctly, it can result in structural problems or safety issues down the line. Inaccurate measurements can also result in costly rework and delays, as well as damage to a company’s reputation and credibility.

In addition to the practical considerations, calibration of an optical level is also required by industry regulations and standards. Companies that fail to comply with these requirements can face penalties, fines, or legal action.

Overall, calibration of an optical level is essential to ensure accurate and reliable measurements in construction and engineering projects. It helps to prevent errors, ensure safety and quality, and maintain compliance with industry standards.

Getting your optical level calibrated from an ISO 17025 accredited laboratory offers several advantages, including:

- Assurance of accuracy: Calibration from an ISO 17025 accredited laboratory provides assurance that the calibration is done to the highest level of accuracy possible. ISO 17025 accreditation ensures that the laboratory has met stringent international standards for testing and calibration.

- Compliance with industry regulations: Many industries require calibration from ISO 17025 accredited laboratories to comply with industry regulations and standards. For example, construction and engineering industries require calibration to comply with local, state, and federal regulations.

- Traceability of measurements: Calibration from an ISO 17025 accredited laboratory provides traceability of measurements back to national and international standards. This ensures that your measurements are accurate and reliable.

- Confidence in results: Calibration from an ISO 17025 accredited laboratory gives you confidence in the results of your measurements. The accreditation provides independent verification that the laboratory has the necessary skills, knowledge, and equipment to provide accurate calibration.

- Reputation and credibility: Calibration from an ISO 17025 accredited laboratory enhances the reputation and credibility of your business. It demonstrates to clients and stakeholders that you are committed to quality and accuracy in your measurements.

Overall, getting your optical level calibrated from an ISO 17025 accredited laboratory provides assurance of accuracy, compliance with industry regulations, traceability of measurements, confidence in results, and enhances the reputation and credibility of your business.